Correctly plan and calculate power supplies

At the technical heart of every building, the distribution board, careful planning and calculation of the power supply units is crucial to the smooth operation of automation technology.

Designing the right power supply units for 24V devices in a distribution cabinet is a task that requires both technical expertise and foresight planning.

In this blog, we highlight some of the most important aspects that need to be considered when planning power supply units for building automation systems, and discuss the challenges that can arise.

1. Calculate total output

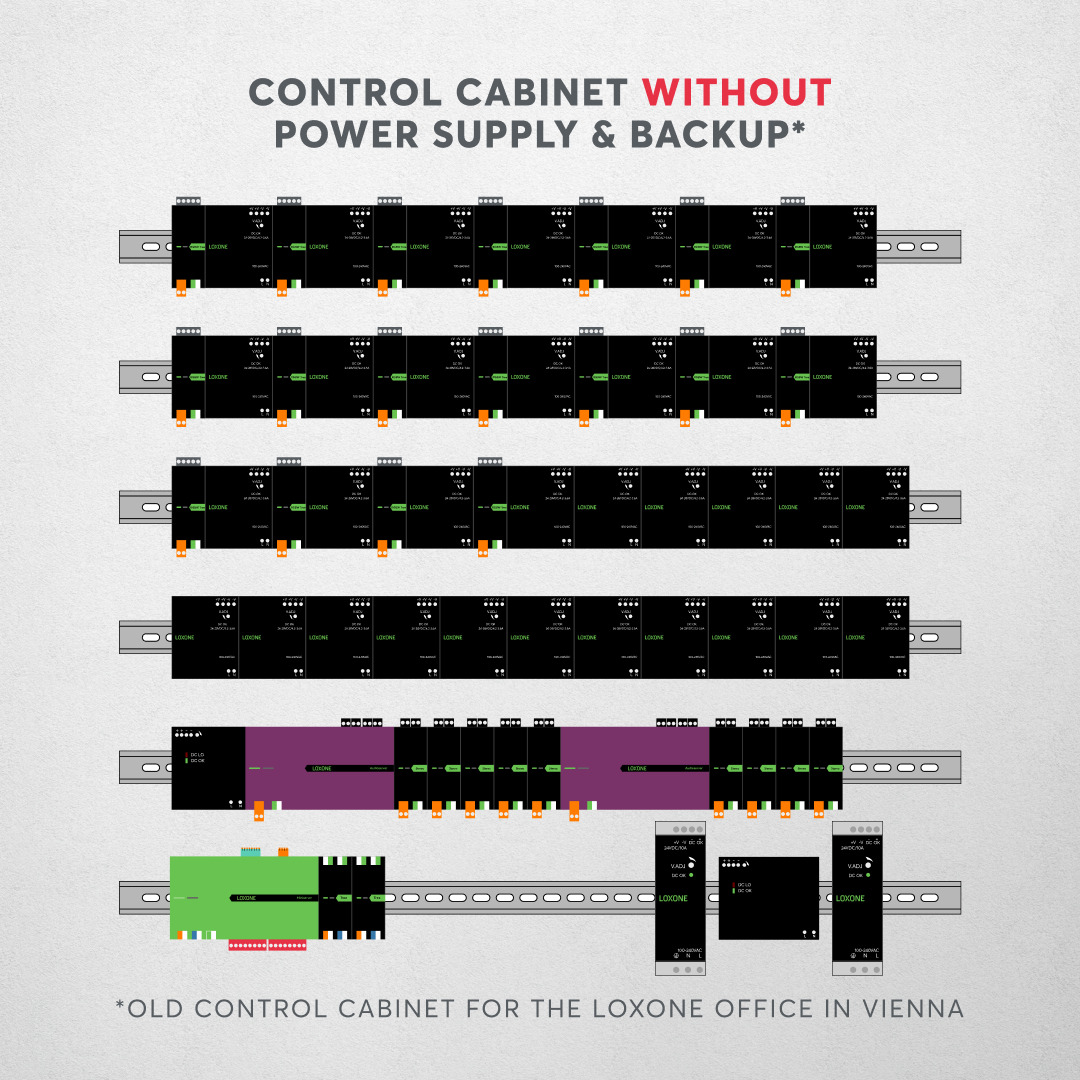

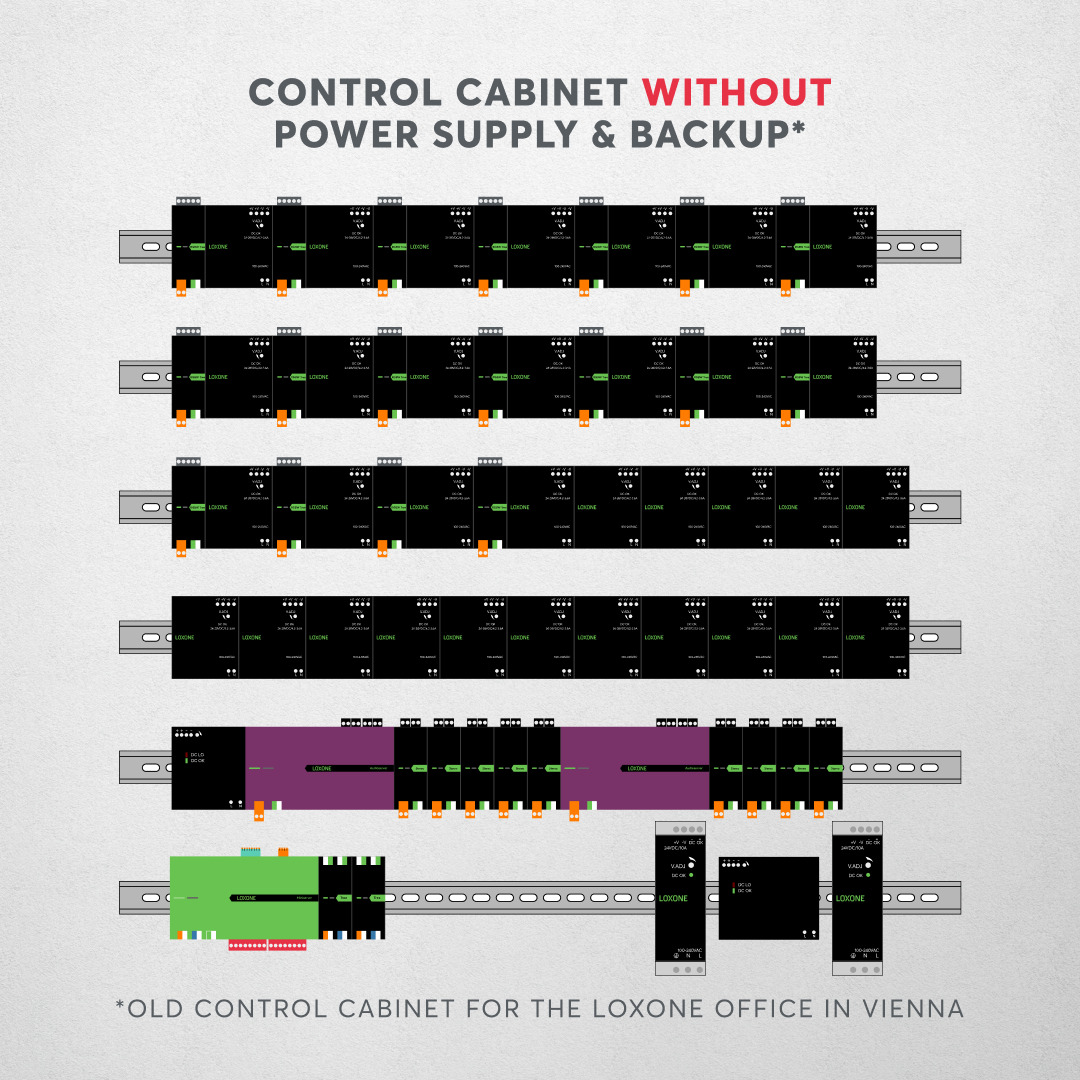

The first and most important step is to calculate the total power required by all 24V devices. This calculation must not only take into account the current demand, but also allow for future expansions. If the power supply units are undersized, this can lead to overloading and failures. On the other hand, when oversizing, the maximum total output of all devices is often wrongly assumed and, as a result, an unnecessarily large number of power supply units are installed, which takes up space in the distribution board and costs money. One variable is particularly important here – the so-called simultaneity factor.

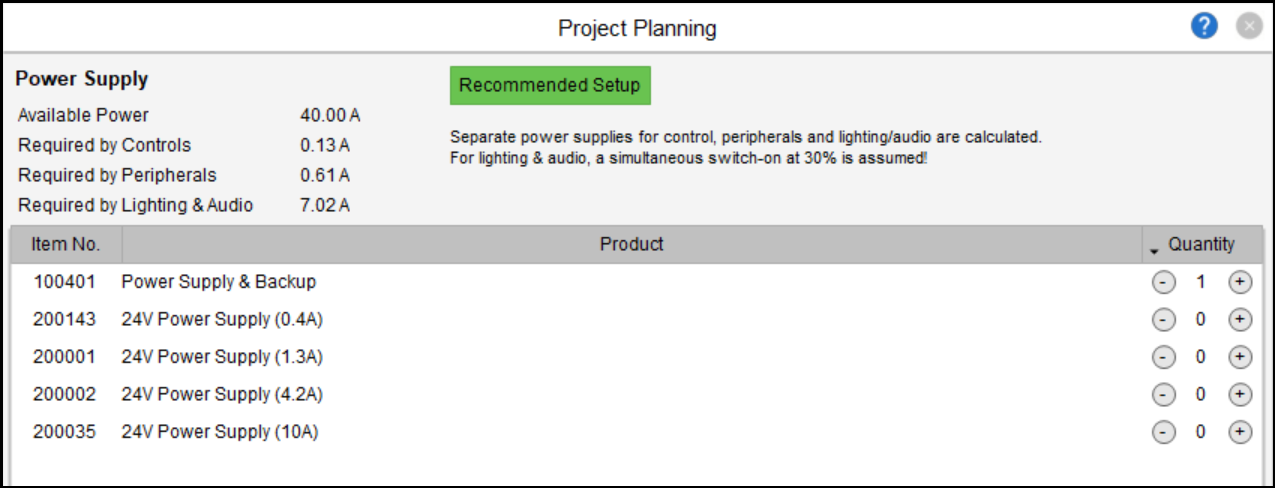

The Loxone Project Planning tool calculates the required power fully automatically based on the planned components.

2. Simultaneity Factor

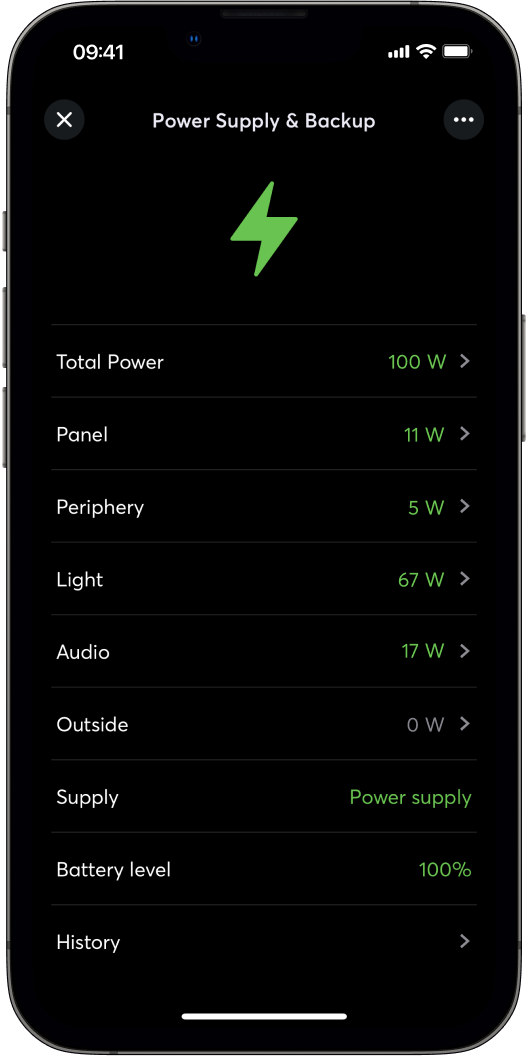

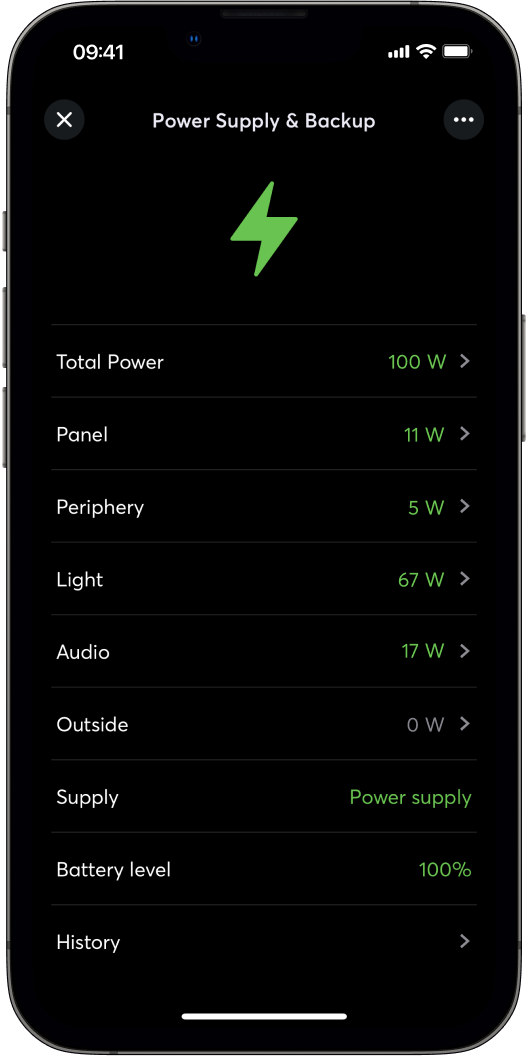

This is used for components such as lighting and audio and reflects the probability of how many of these components are 100% active at the same time. In private construction, we are talking about a factor of 0.3, i.e. 30% of the total power (with centralised power supply).

For the cabinet-based devices, such as the Miniserver and any Extensions, and also for all peripheral devices, such as Presence Sensors or Touch switches, 100% of the required power is calculated.

Light calculation example:

The 5m Loxone LED Strips has a maximum power consumption of 86W. In Loxone Config, however, switching on is split between the three RGB channels and the W channel. This means that a maximum of 64W can be activated when using this 5m colour LED strip (2.66A instead of 3.58A).

Power consumption per channel and 5m strip:

Red: 20W

Green: 23W

Blue: 21W

Warm white: 22W

Max.: 86W

Measured values from practice:

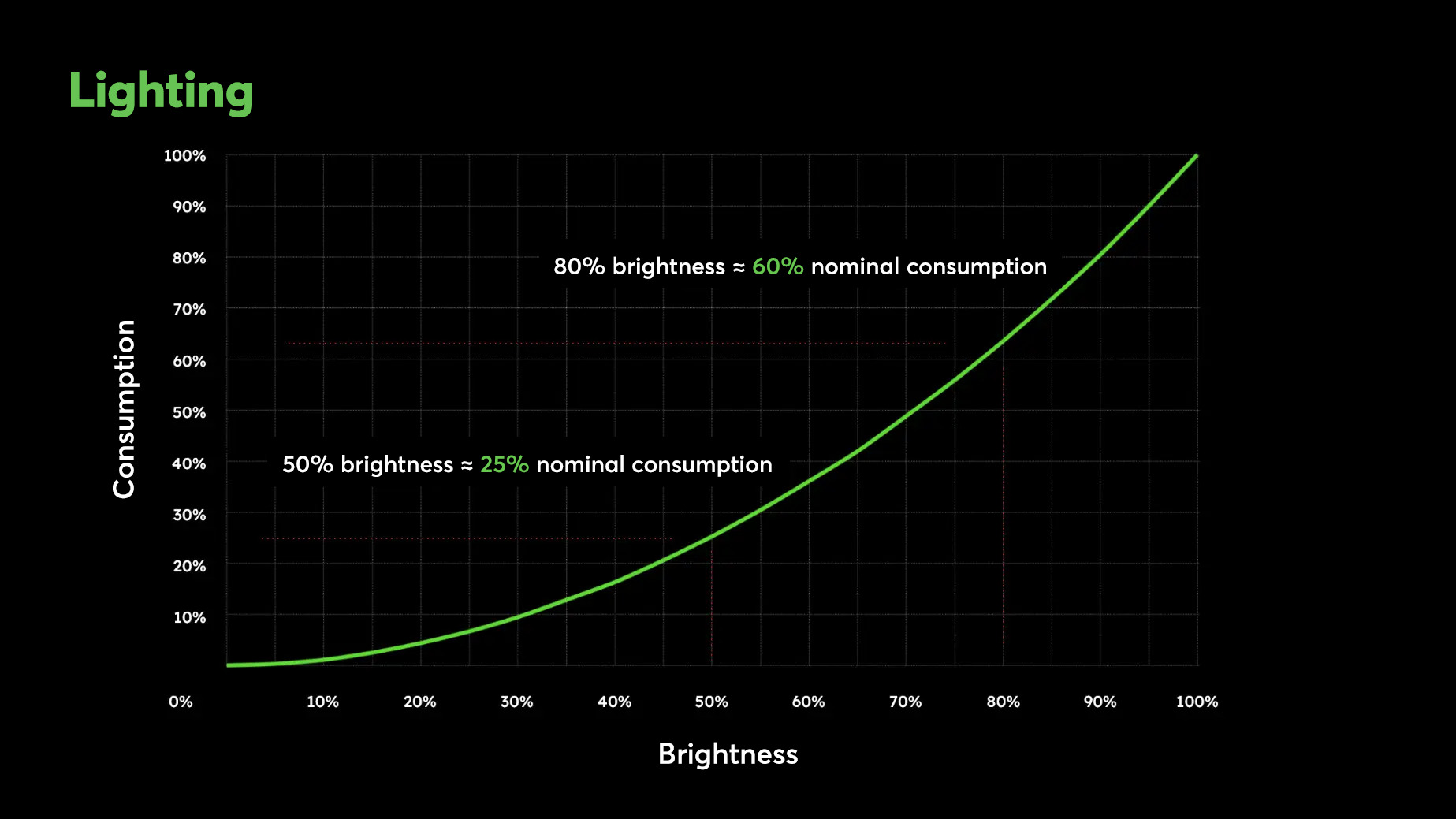

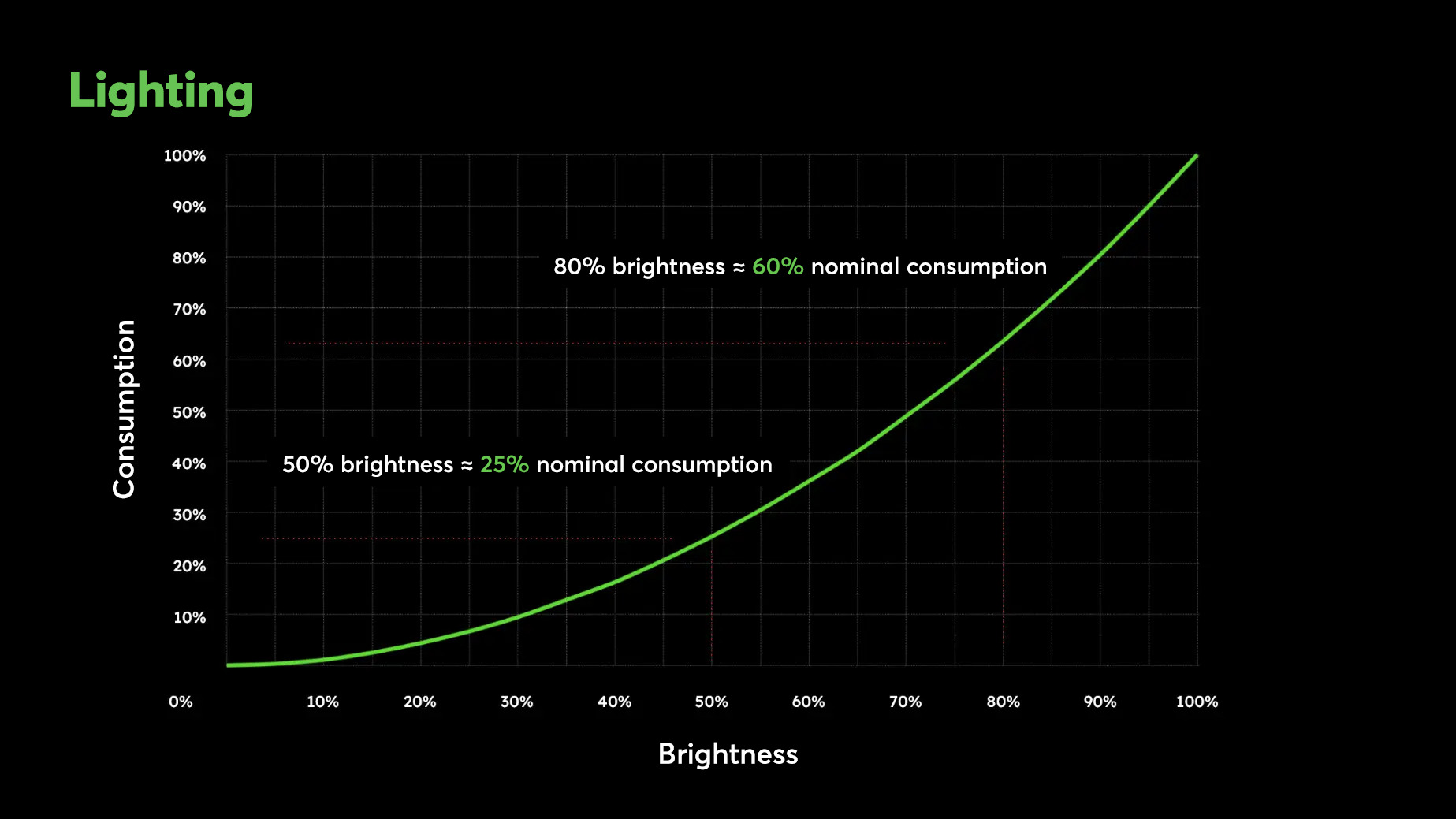

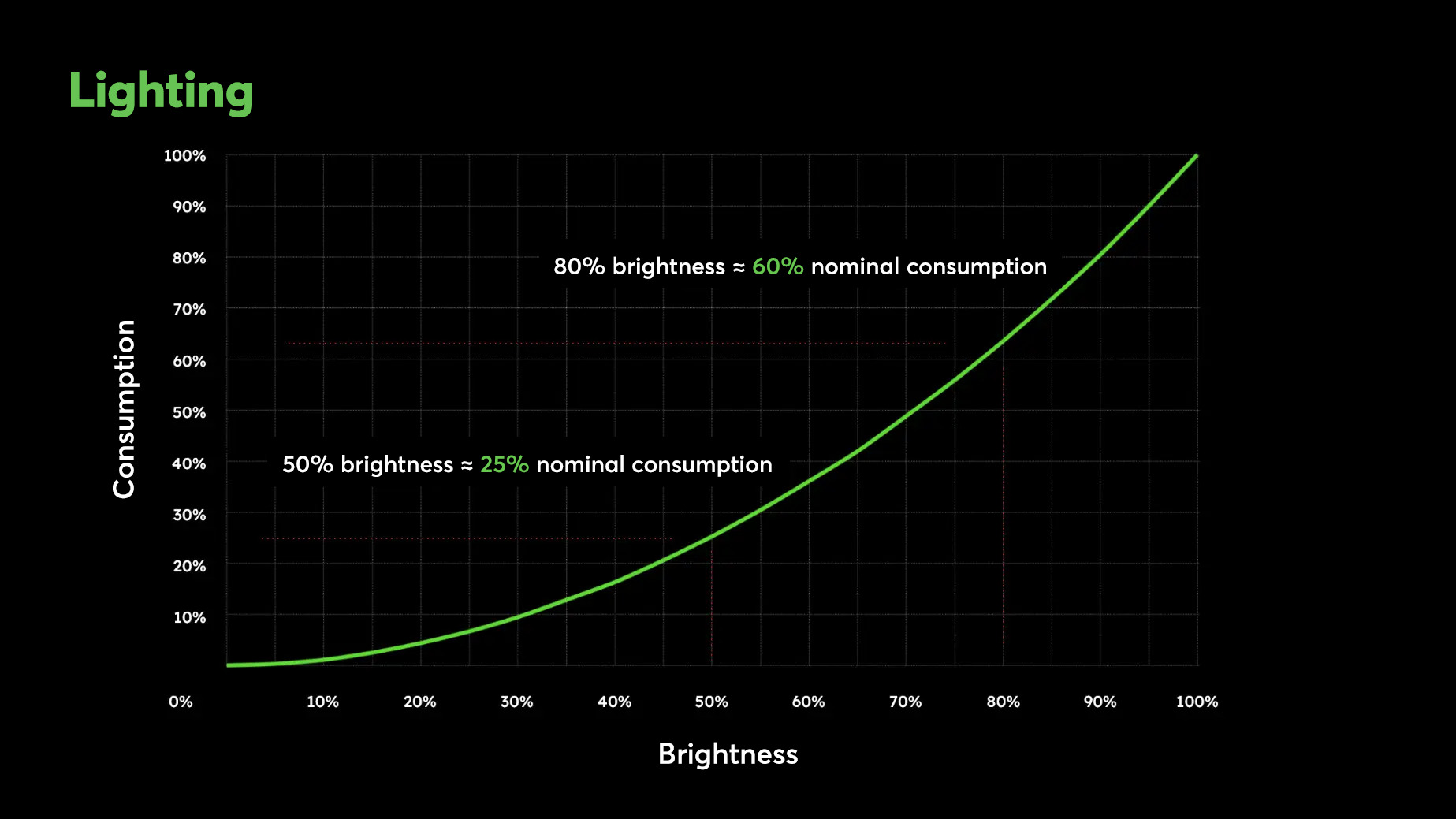

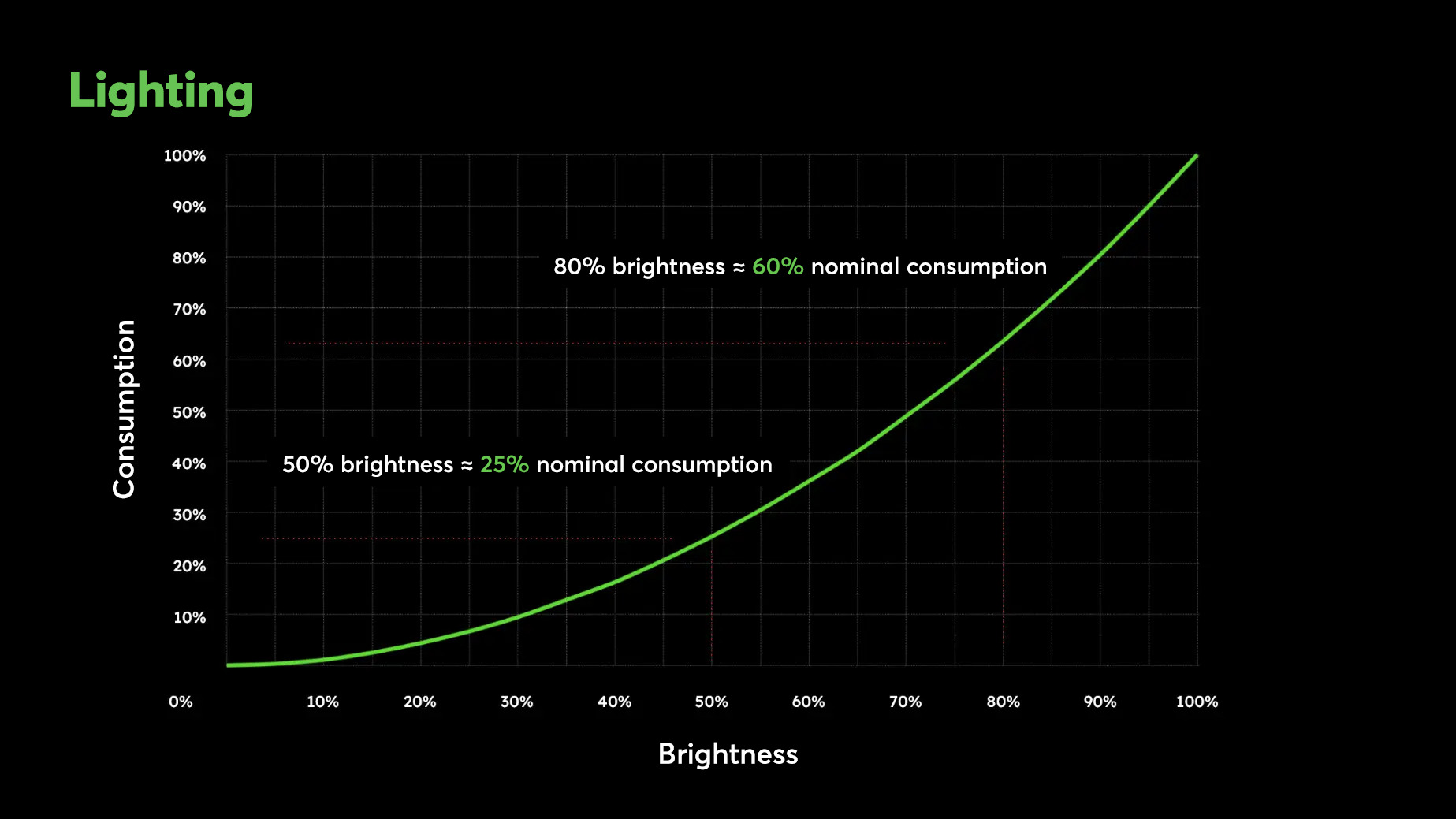

PWM spots as well as the Loxone Tree Spots, for example, require only 60% of the power at 80% of the brightness.

80% brightness – 4.92W

100% brightness – 7.5W

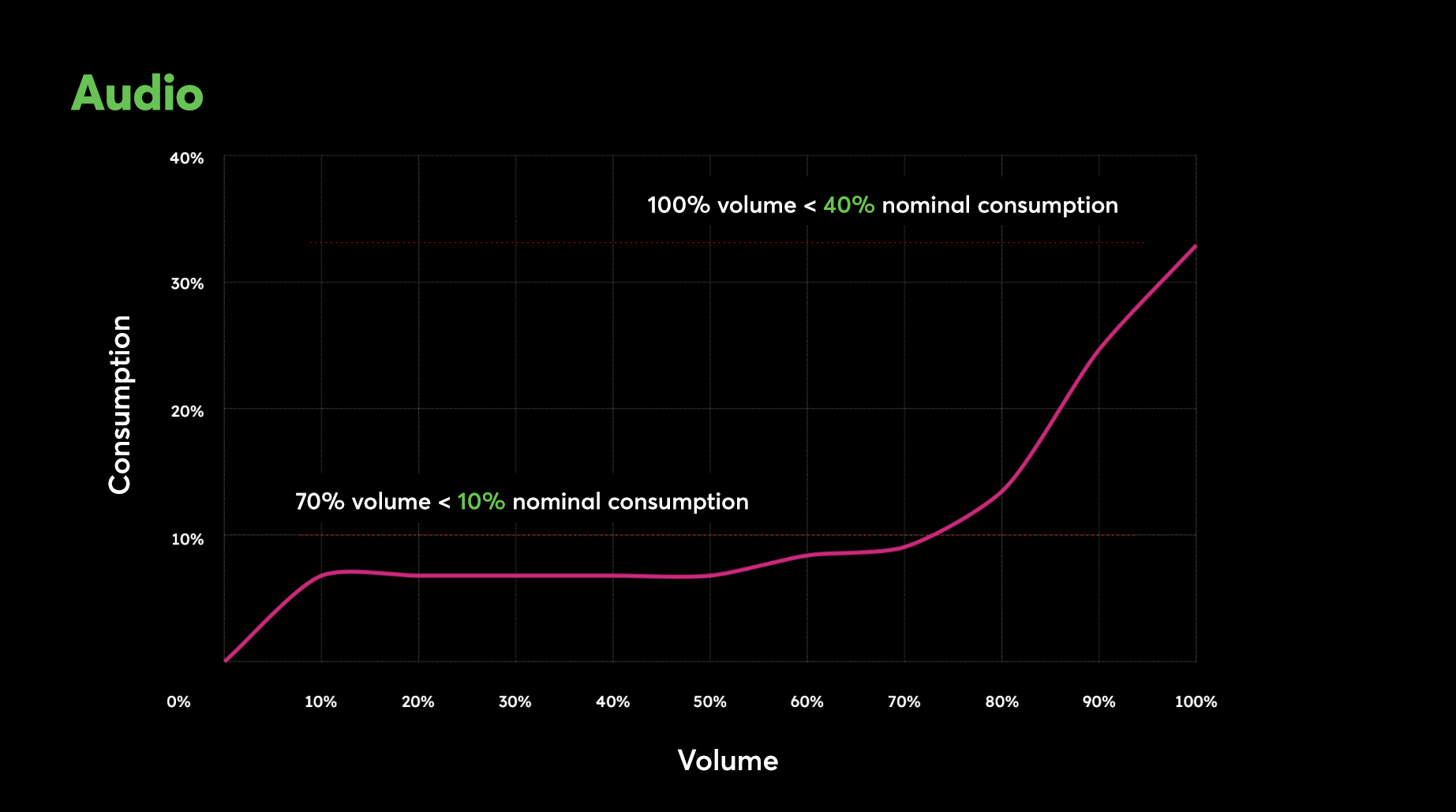

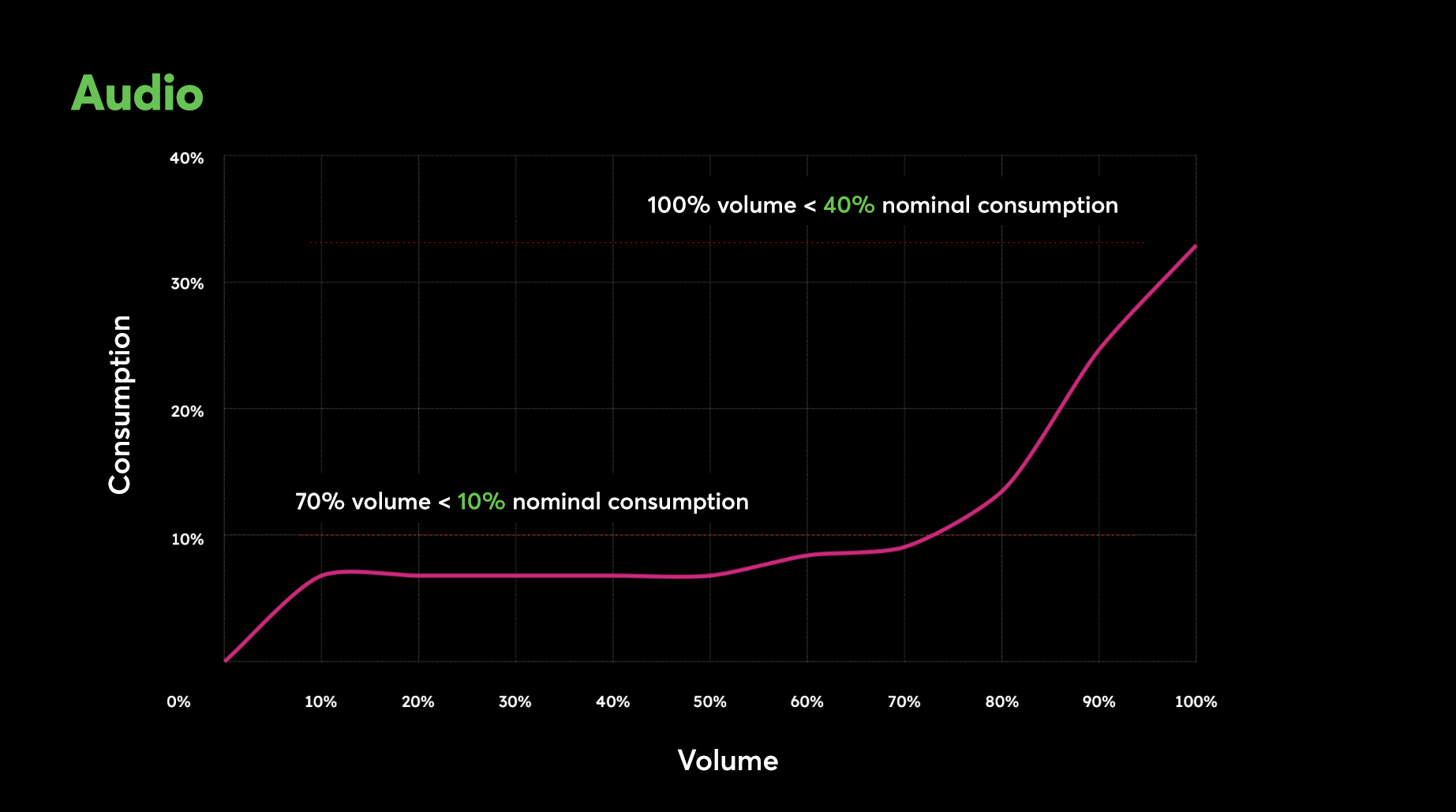

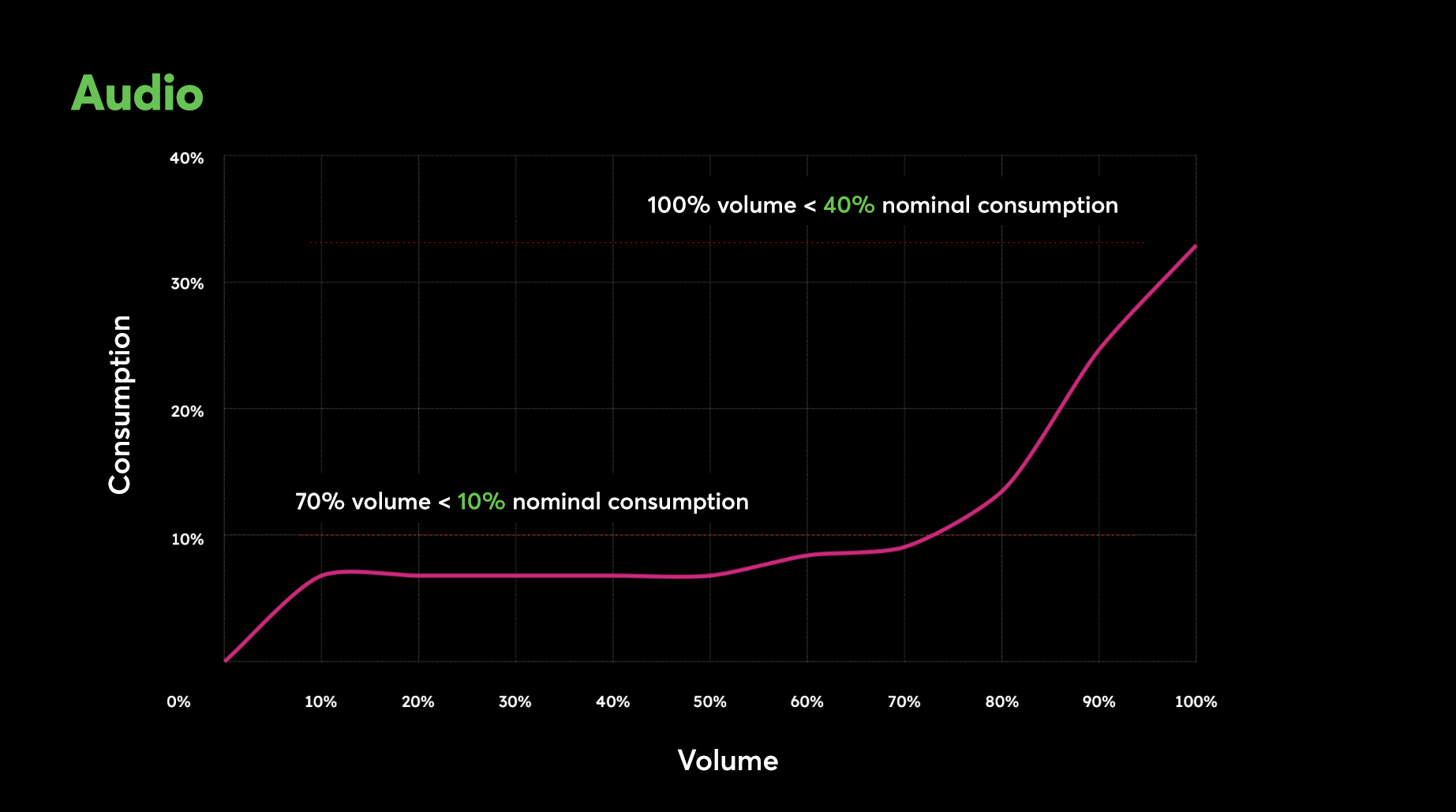

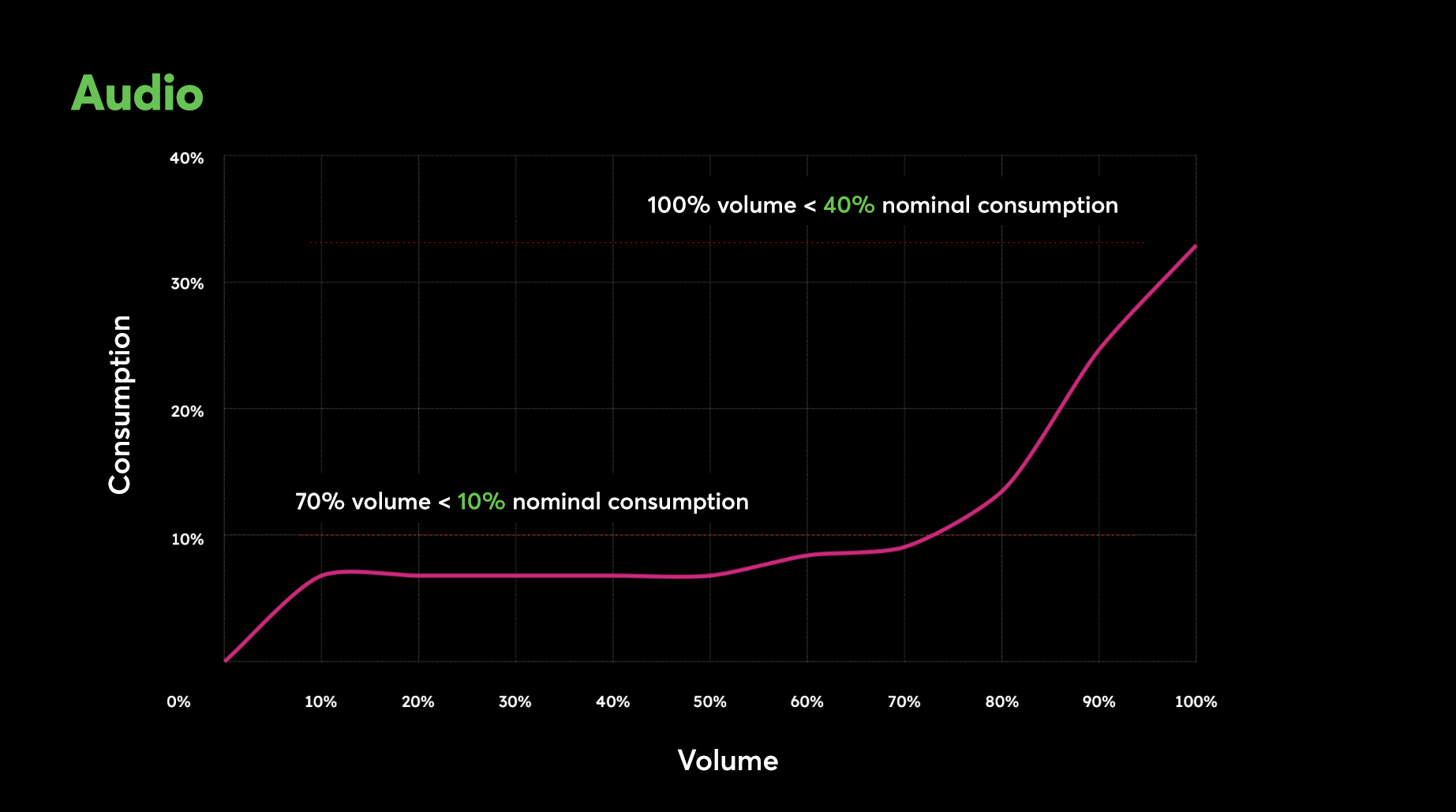

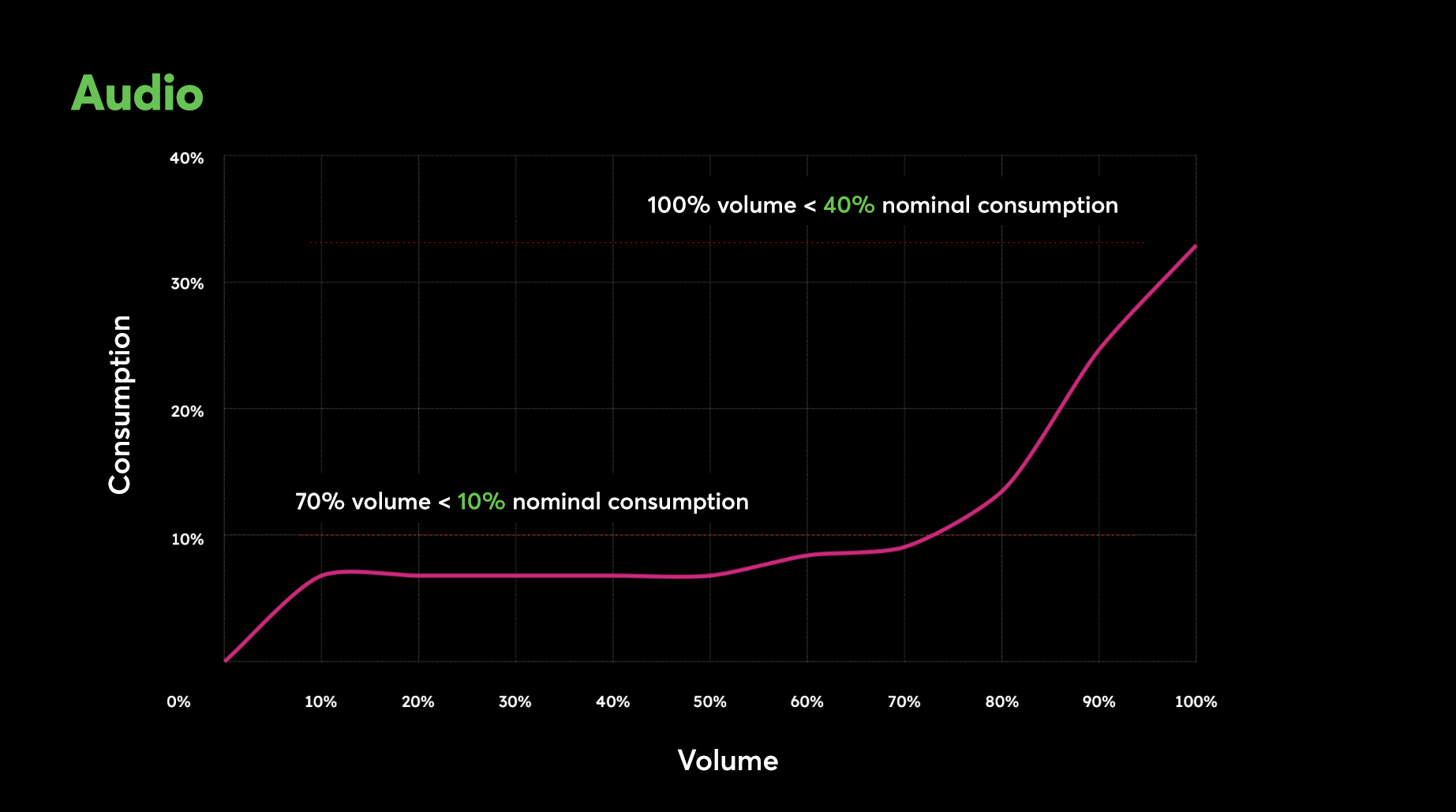

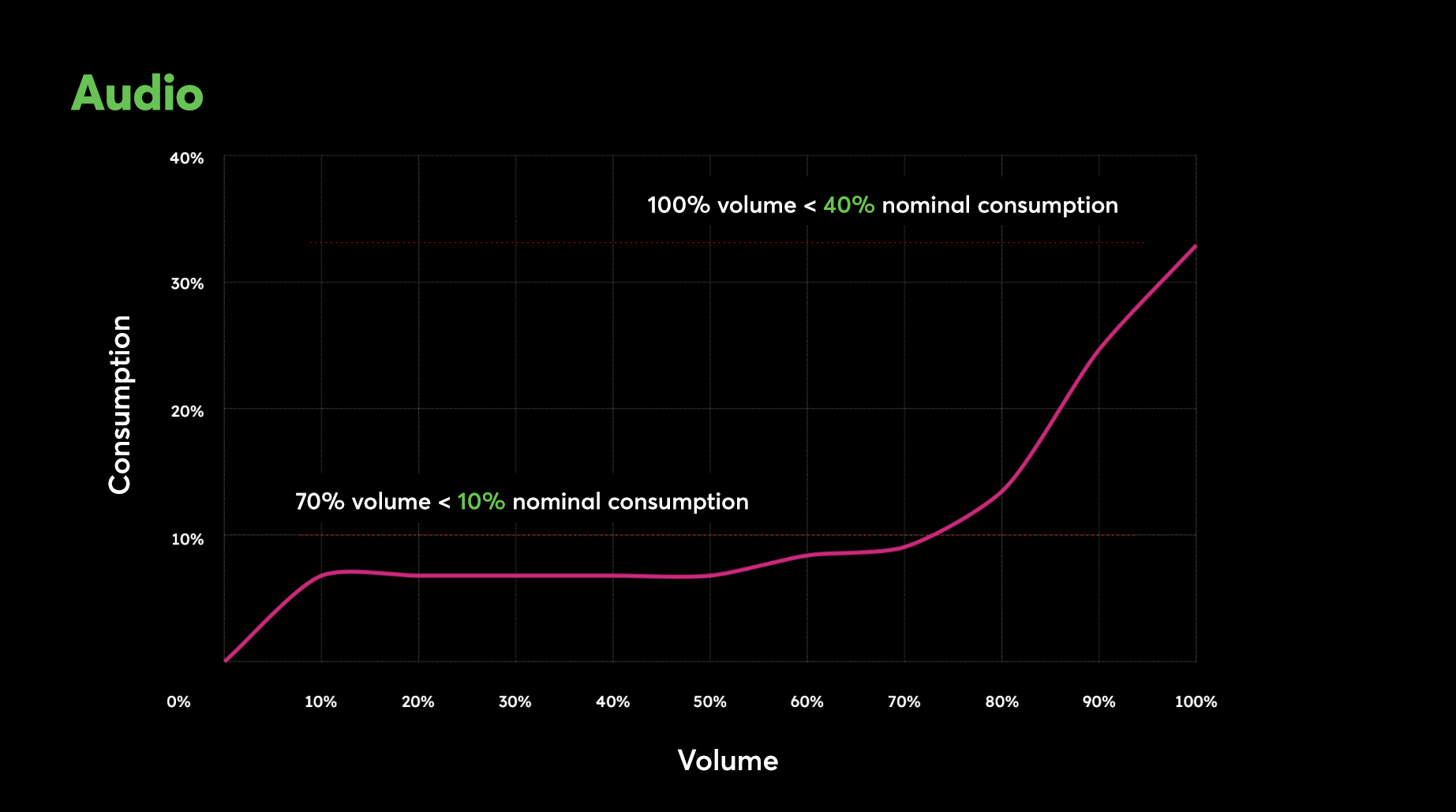

Audio calculation example:

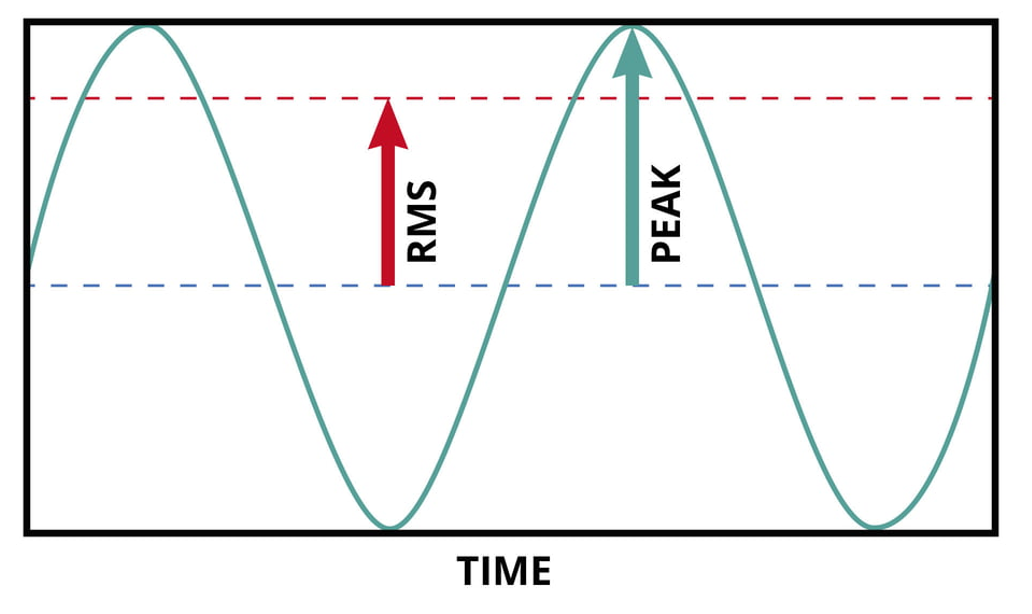

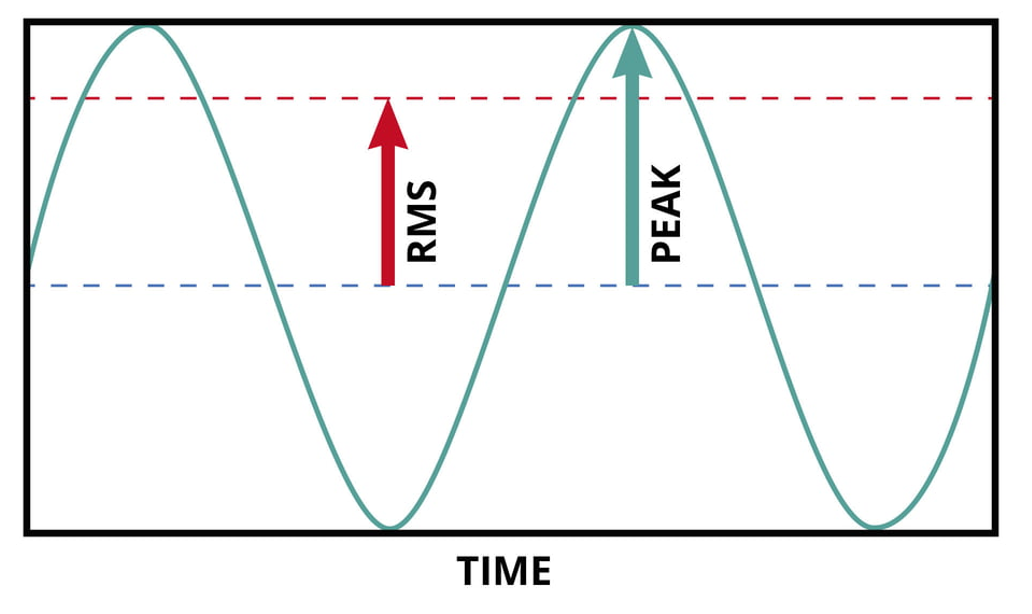

An output of the Loxone Audioserver is calculated with an RMS power of 18W. This power would be required at maximum switch-on volume. However, only with very low-frequency music.

Measured values from practice:

With quiet music, only 40%* of the total power is required at 100% volume.

Hotel California – Eagles

25% volume – 3.2W

100% volume – 9.6W

Animals – Martin Garrix

25% volume – 3.4 W

100% volume – 14.4W

Measured against the WALL Speaker.

*the values refer to the maximum measured current, as this is very dynamic with music.

3. Plan a power reserve

It is advisable to use a power reserve of at least 20% above the calculated total output. This reserve helps to absorb unexpected load peaks and provides scope for later expansions of the system.

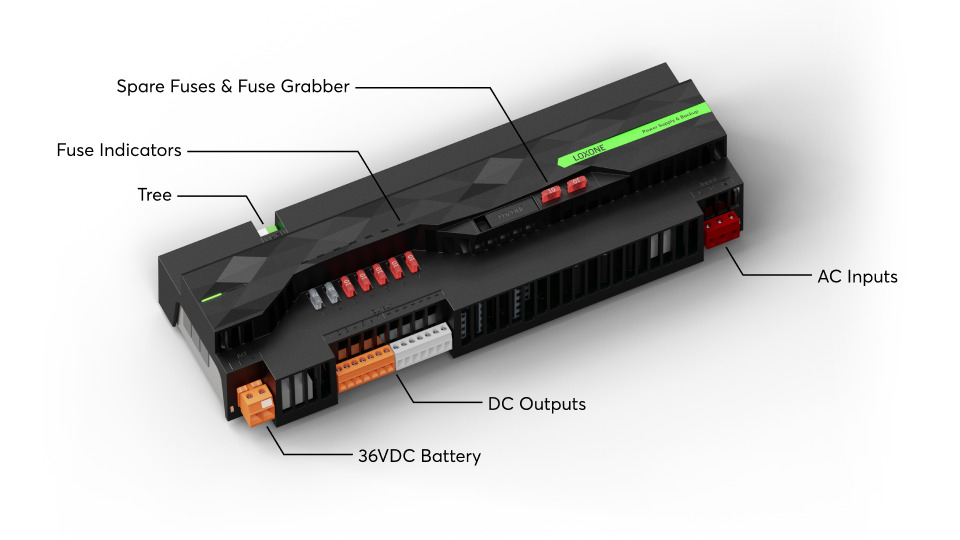

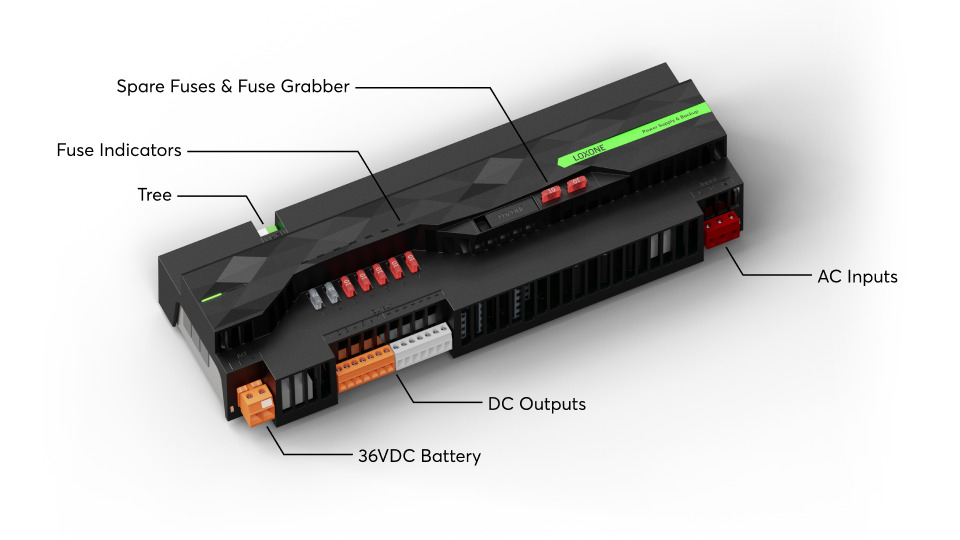

The Power Supply and Backup can output 60A for 10 seconds instead of the maximum permissible 40A according to the datasheet.

4. Quality and reliability

The selection of power supply units should not only on the basis of their performance capacity. High-quality power supply units with good efficiency and protective functions such as short-circuit protection, overload protection and thermal protection are crucial for the longevity and safety of the entire system.

Electromagnetic compatibility (EMC):

Installing several power supply units in a distribution board can lead to electromagnetic interference. It is important to choose power supply units that perform well in terms of EMC and to take additional shielding measures if necessary.

5. Consider heat output

Components should be placed strategically within the cabinet to avoid overheating:

Power supply units: As power supplies are one of the largest sources of heat, they should be placed in areas with good ventilation. It is advisable not to place them directly next to other heat sources or in the centre of the distribution board to minimise heat accumulation. If possible, they should be installed near ventilation slots or in positions with natural airflow.

Automatic switches (circuit breakers): If possible, these should be placed at the beginning of the distributor where they are easily accessible. The heat generated by the likes of breakers is generally lower than that of power supply units or the control unit, which is why their positioning is more flexible.

6. Cabling and connections

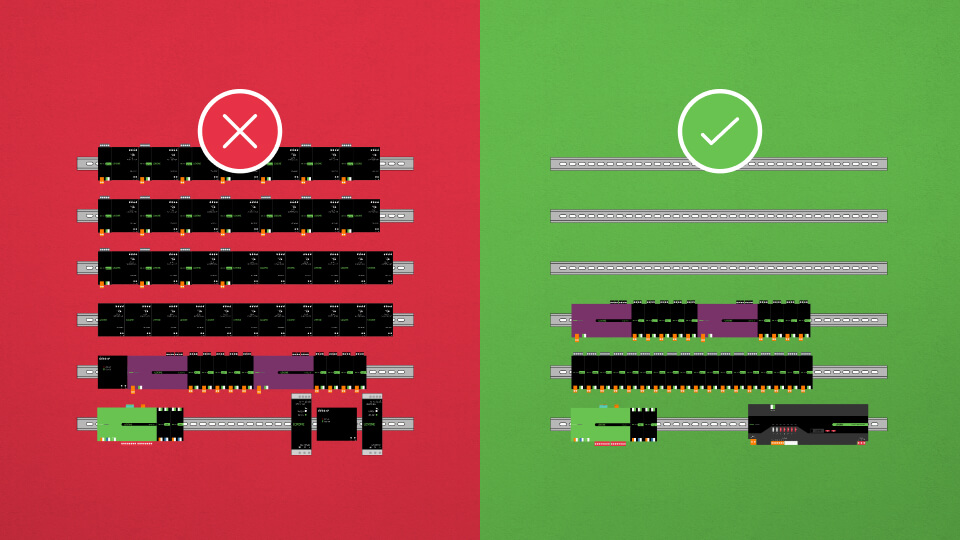

More power supply units also means more effort in the cabling. Every terminal, every connection and every screw is an additional source of error. In the case of a cabinet build, a 2-5% margin of error of all connections is taken into account. If the total number of connections can be minimised, this not only reduces installation time, but also potential troubleshooting. A nice additional effect is the space saved in the cabinet overall.

Proper cabling and a secure connection are therefore crucial for the reliability of the power supply. Make sure that the cable cross-sections are sufficiently dimensioned and that all connections are firmly connected.

7. Maintenance and monitoring

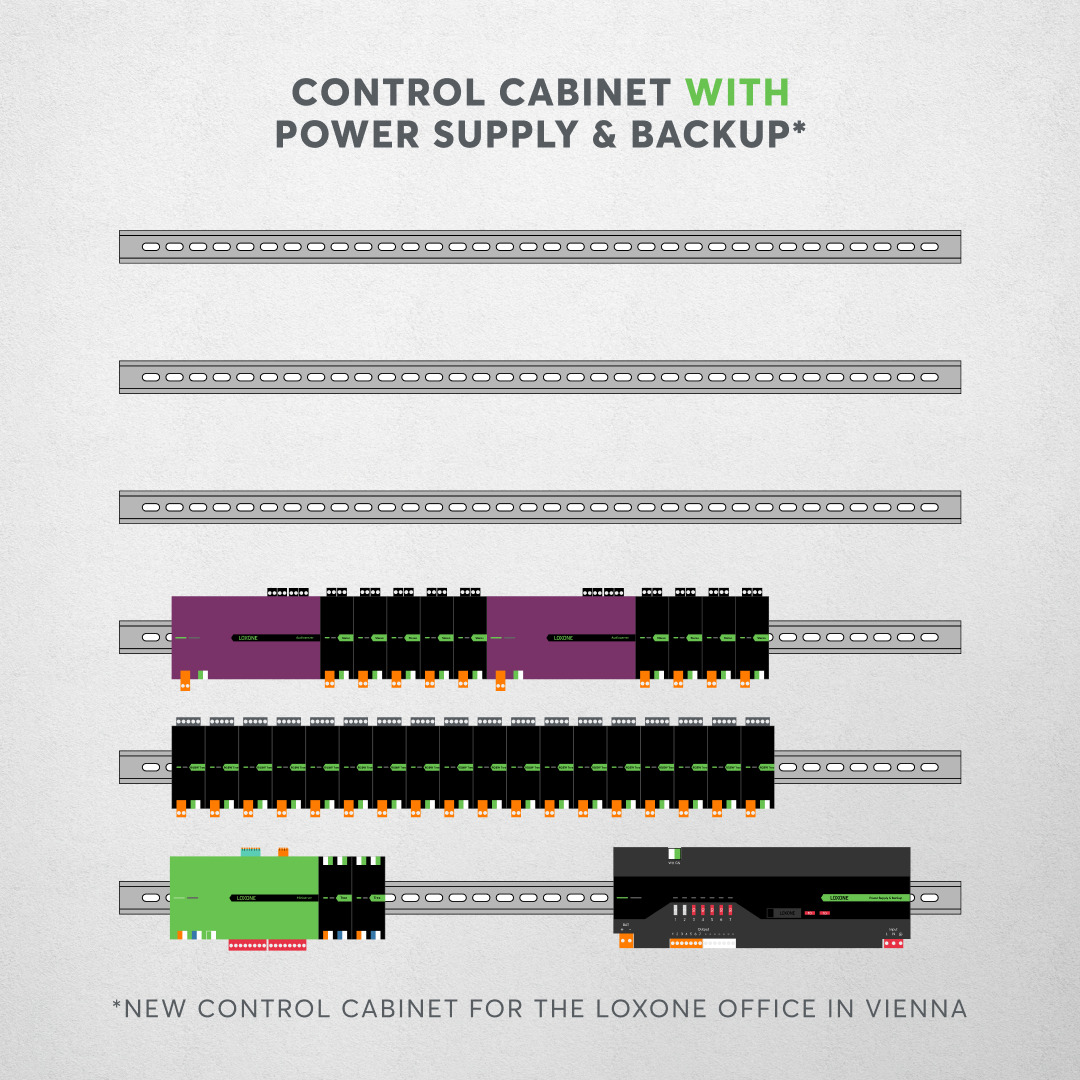

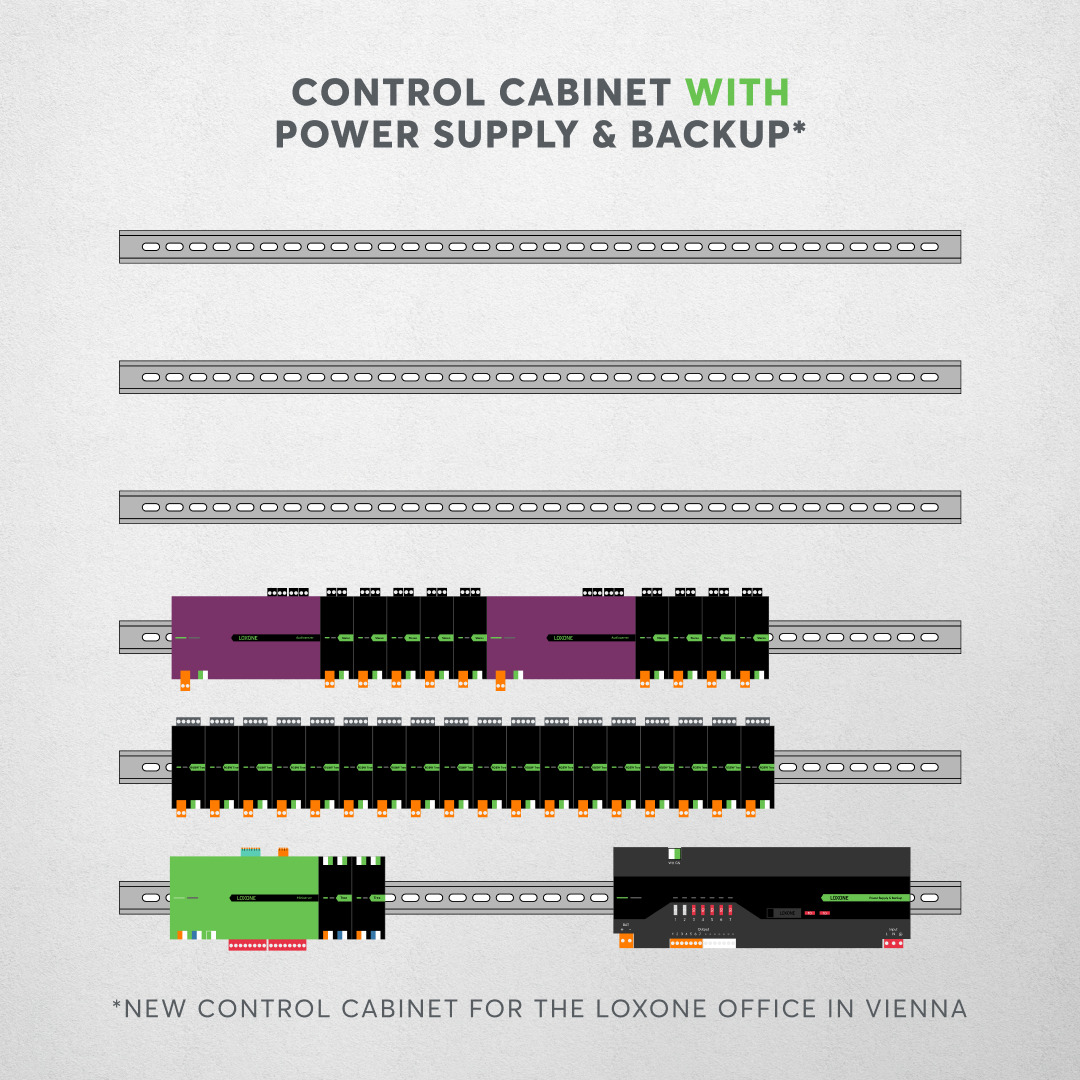

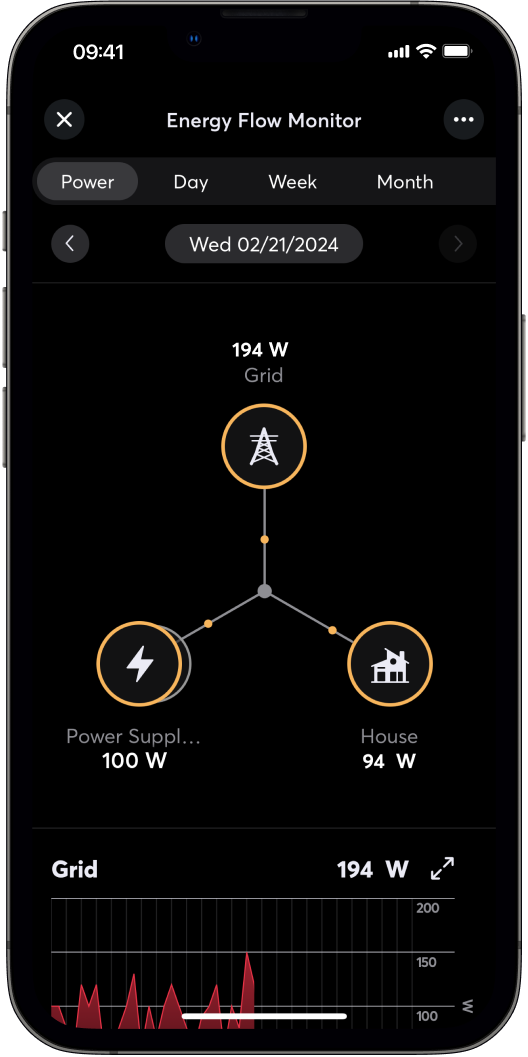

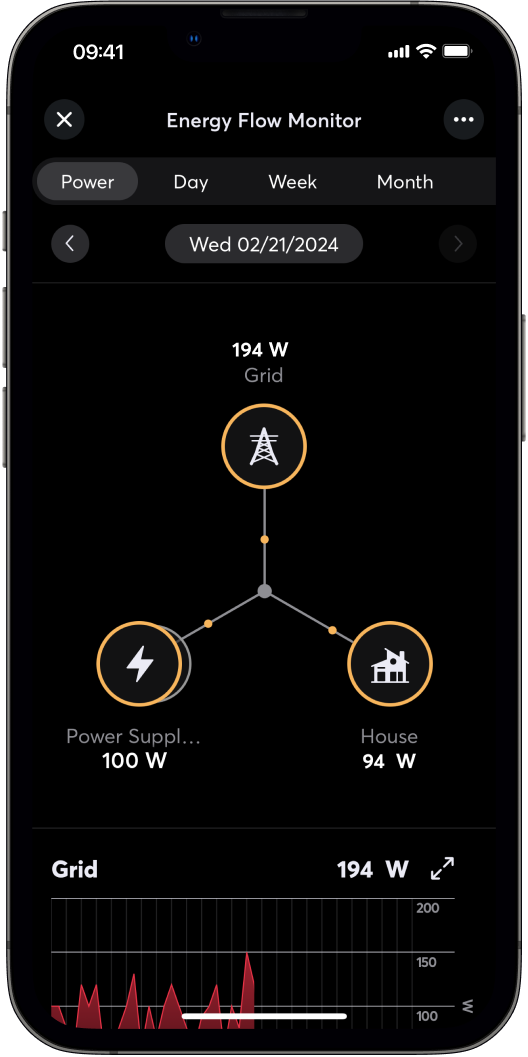

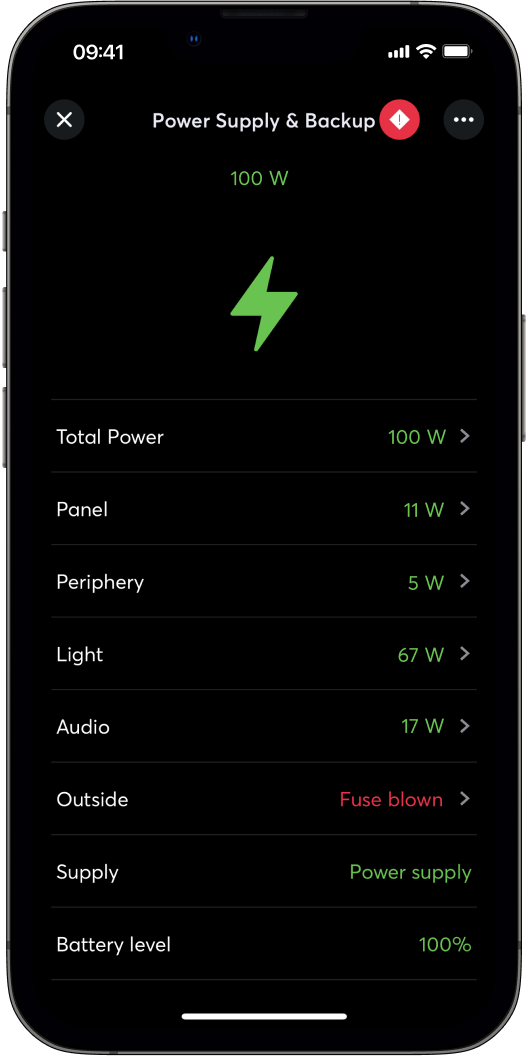

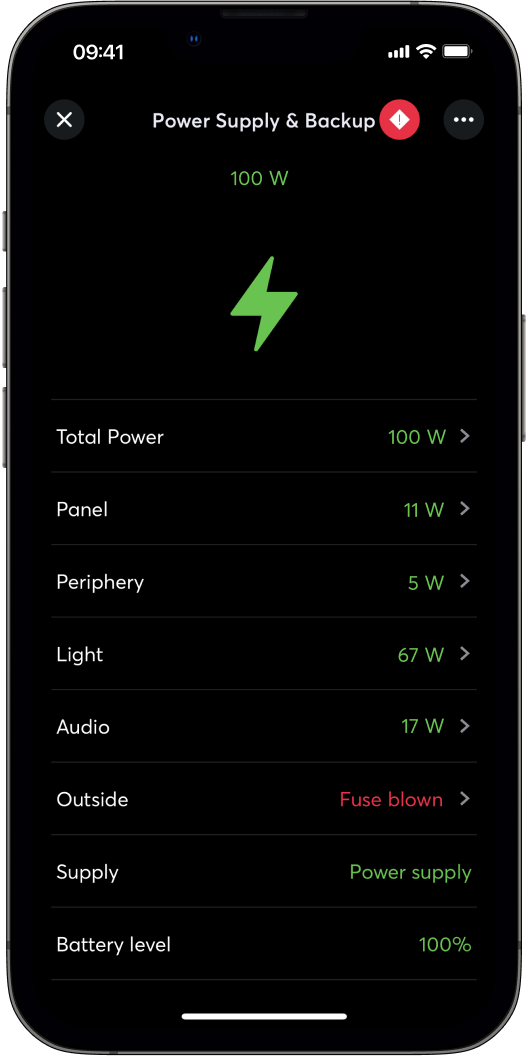

In the event of a short circuit or overload of the cable, each outlet should be secured. To avoid lengthy troubleshooting, it makes sense to monitor these fuses so that you are notified when they have tripped. In addition, it makes sense to measure energy consumption in order to identify potential savings and avoid energy wasters. Our recommendation: the Power Supply & Backup as an all-in-one solution.

The biggest challenge is often the dynamics of the project. Changes in the planning phase, or unexpected extensions. To summarise, the planning of power supply units for building automation is a task that goes far beyond the simple addition of performance values. It requires a comprehensive understanding of the technical requirements, forward-looking planning and the ability to react flexibly to unforeseeable challenges.

Interested in Loxone?

Whether you want Loxone installed or you want to start offering your customers Loxone, speak to us about making that happen.