Dit maakt een veilige en probleemloze werking van alle apparaten mogelijk.

De algemene regels van de elektrotechniek en de landspecifieke voorschriften en normen moeten in acht worden genomen.

Deze pagina geeft basisinformatie en verwijst naar verdere informatie over bedrading.

Voer werkzaamheden alleen uit als de installatie spanningsloos is.

Dit beschermt zowel jezelf als de apparaten tegen schade.

Loxone Partners, onze support is beschikbaar om vragen over de installatie te beantwoorden.

INHOUD:

Voeding

PELV of SELV

Interfaces

Verdelerstructuur

Voeding

De Miniserver en de meeste Loxone apparaten voor distributie-installatie worden geleverd met een nominale spanning van 24VDC.

Sommige apparaten hebben een groter toelaatbaar spanningsbereik, zie de datasheets.

De spanning wordt geleverd door voedingseenheden van verschillende prestatieklassen.

Parallelschakeling is alleen toegestaan met voedingseenheden die daarvoor geschikt en geconfigureerd zijn.

Het wordt sterk aanbevolen de 24V-voeding in meerdere circuits te verdelen.

Dit voorkomt effectief een totale uitval van het gehele systeem in geval van kortsluiting.

Afzonderlijke circuits kunnen worden gevormd door meerdere voedingsunits te gebruiken, of door meerdere afzonderlijk gezekerde circuits op één krachtige voedingsunit te gebruiken.

De keuze van de geleiderdoorsnede en de bijbehorende zekering moet ook voor 24V worden uitgevoerd volgens de regels van de elektrotechniek.

Voor 24V bedrading binnen de verdeelkast kunnen bijvoorbeeld doorverbindingsdraden worden gebruikt.

In het gebouw wordt voor de 24V-voorziening de Loxone Tree kabel met twee verschillende geleiderdoorsneden gebruikt.

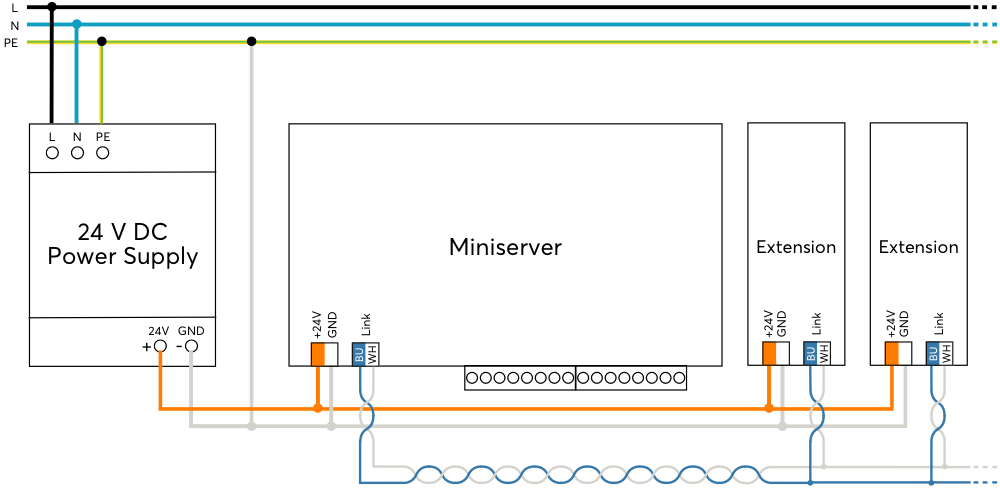

Voorbeeld:

Eén voedingseenheid of -circuit voor de voeding van Miniserver en uitbreidingen in de hoofddistributie.

Eén voedingsunit of -circuit voor de voeding van uitbreidingen in een subdistributie.

Eén voedingsunit of -circuit voor de voeding van apparaten met een laag vermogen (Loxone Touch, Aanwezigheidsmelders, sensoren…).

Een voedingsunit of -circuit voor de voeding van apparaten met een hoog vermogen (24V LED-verlichting…).

De negatieve polen (GND’s) van de afzonderlijke voedingen moeten met elkaar worden verbonden.

Dit is nodig omdat de communicatie van de eenheden (bijv. via Link, Tree) naar een gemeenschappelijk potentiaal verwijst.

Als deze verbinding ontbreekt, kunnen er storingen optreden in de gegevensoverdracht of, in het ergste geval, schade aan de interfaces.

PELV of SELV

Loxone apparaten zijn in principe geschikt voor zowel PELV- als SELV-installatie.

Vaak is een zuivere SELV-installatie niet mogelijk, omdat via apparaten of geaarde kabelafschermingen een ongewenste verbinding met de PE-beschermingsgeleider plaatsvindt.

Dit leidt bij een indirecte blikseminslag tot hoge vereffeningsstromen via elektronische apparaten en kan deze beschadigen.

Daarom raden wij aan altijd te kiezen voor de PELV-installatie.

Hiertoe worden de negatieve/GND-uitgangen van de voedingen bewust verbonden met de randaarde/PE.

Dit is weergegeven in het volgende schema:

Apparaten die geen bedrade gegevensoverdracht gebruiken, kunnen ook met SELV worden gebruikt.

Voorbeeld: RGBW Dimmer Air met een eigen voedingseenheid.

Hier is geen PELV- of GND-verbinding met de andere voedingseenheden nodig.

Het is dan een elektrisch onafhankelijk deel van de installatie.

Interfaces

In een Loxone installatie kunnen verschillende bedrade interfaces worden gebruikt.

Deze verschillen in functie en bedrading:

Loxone interfaces:

Link interface: Aansluiten van Extensions

Tree interface: Aansluiten van Tree apparaten

Tree Turbo: Aansluiten van Stereo Extensions

Algemene interfaces:

Modbus: Aanslutien van Modbus apparaten

RS485: Aansluiten van RS485 apparaten

RS232: Aansluiten van RS232 apparaten

DMX: Aansluiten van DMX apparaten

1-wire: Aansluiten van 1-wire sensoren

Tips voor verdelerstructuur

De keuze en het ontwerp van een verdeler is sterk afhankelijk van de installatie en de plaatselijke voorschriften.

Als alle in- en uitgangen in de verdeler door middel van verlengstukken moeten worden aangesloten, is uiteraard een grote verdeler nodig.

Kleinere verdelers zijn voldoende als sensoren en actuatoren in het gebouw kunnen worden geplaatst met behulp van Tree and Air apparaten. Dit vermindert ook de bedrading.

Als verlichting en audio ook centraal moeten worden gevoed vanuit grote voedingen, moet in beide gevallen extra ruimte worden ingepland.

Er moet voldoende ruimte worden voorzien als reserve voor toekomstige uitbreidingen.